- Introduction

- Details

- Technical Data

-

- Commodity name: Digital Finishing Digital Robot 2000A

- Commodity ID: Digital Robot 2000A

Digital Robot 2000A is a fully automated four-clamp perfect binder with high flexibilty for off-line and near-line book binding production for on-demand printing.

Digital Robot 2000A

Flexible Print-On-Demand Perfect Binding Solution

Digital Robot 2000A is a fully automated four-clamp perfect binder with high flexibilty for off-line and near-line book binding production for on-demand printing. It features fully automated set-up, integrated book thickness measurement, short changeover time for various binding formats, interchangeable EVA and PUR system (option), which makes Digital Robot 2000A an ideal solution for both digital and offset production.

Outstanding Features:

♦ High Production Efficiency: Binding production speed can reach up to 1,600 books/hour, together with best-in-class binding quality for both digital and offset production.

♦ User Friendly and Easy Operation: User-friendly operation interface and automatic error diagnostic system insure consistent high quality production by any operator.

♦ Modular Design with Flexible Extensions: Modular design provides broad connectivity to digital three-knife trimmer and digital stacker to achieve an intergrated production line.

♦ Optional PUR Gluing System: User-oriented moveable glue tank design allows changeover between EVA and PUR glue application system in just minutes.

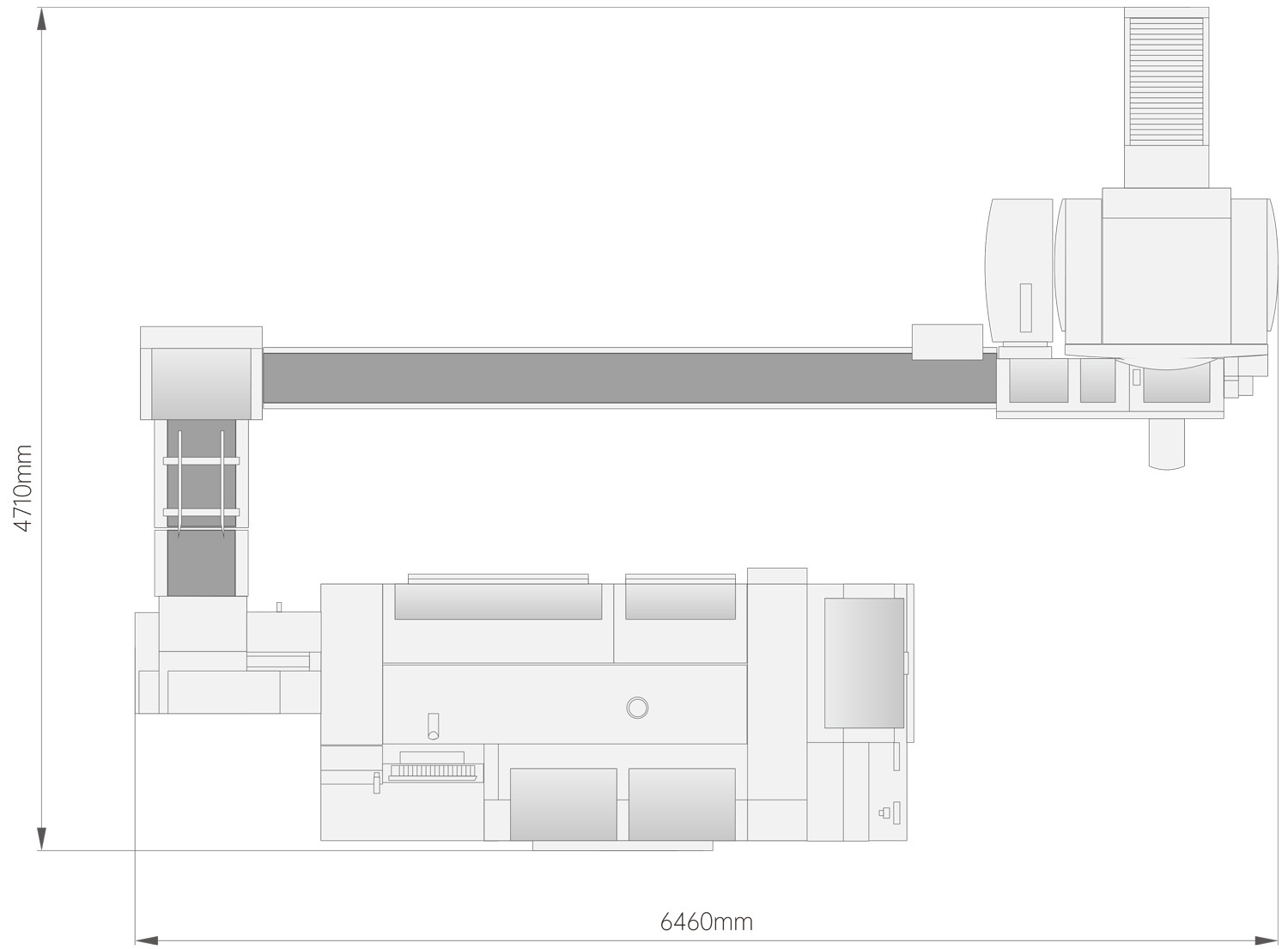

Machine Layout:

Key words:

Key words:- JMD

- roll to stack solution

- book block solution

- webfolder book solution

- web to book block solution

- plowfolder book solution

- digital web finishing

- digital print finishing

- digital finishing solution

-

Touch Screen Control System

The icon-based 10-inch touch screen enables ease of operation.

The control system can memorize 99 jobs and be accessed for repeated jobs.

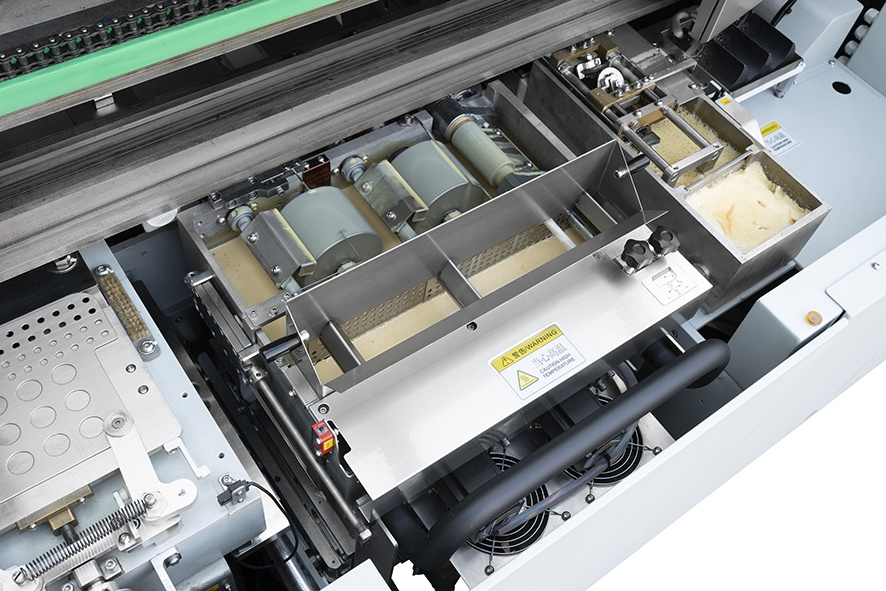

Spine Gluing & Side Gluing Stations

The spine glue length and the side gluing discs are adjusted automatically.

Interchangeable spine gluing system allows easy changeover between EVA and PUR.

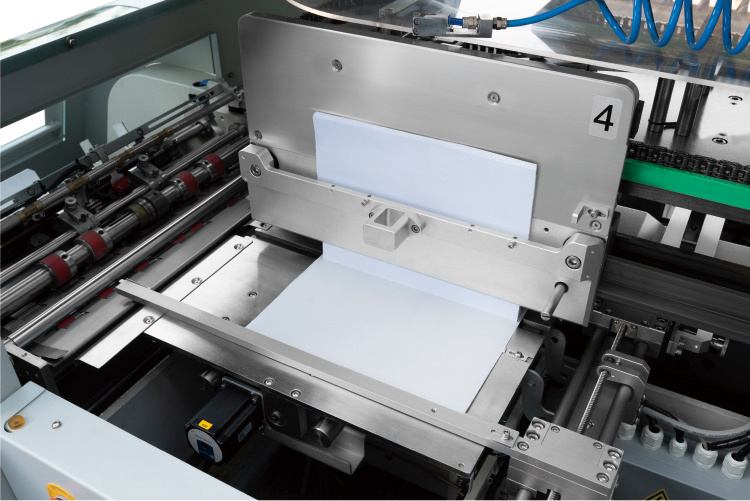

Cover Feeding Station

The special in-feed design from the bottom enables that cover sheets can be added on the fly without stopping the production.

The side gauges of cover feeding station and position of cover scoring wheels are automatically adjusted according to the input data.

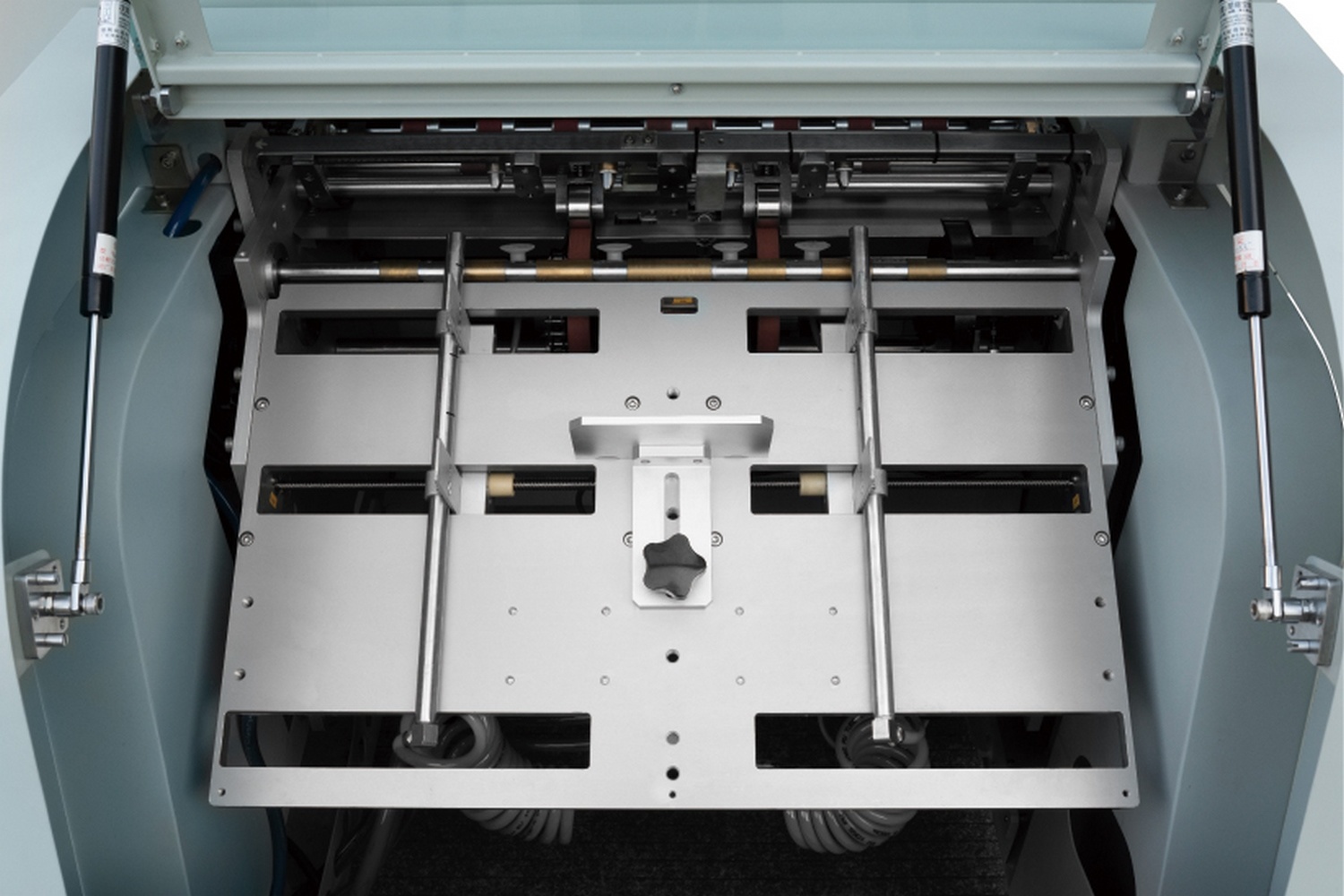

Nipping Station

Thanks to the strong and rigid nipping

mechanism, covers can be precisely and firmly nipped with the book blocks to obtain perfectly-shaped book spines.

The opening width of nipping plates and side gauges are automatically adjusted.

-

Machine Model

Digital Robot 2000A

No. of Clamps

4

Max. Mechanical Speed

2000 c/h

Book Block Length (a)

140-380mm

Book Block Width (b)

120-270mm

Book Block Thickness (c)

3-50mm

Cover Length (d)

140-450mm

Cover Width (e)

250-590mm

Related products

Digital Robot 2000C is designed for the growing demand of efficient in-line production from digital printer to perfect bound books. It features new level of automation, and provides smart connectivity to various types of digital printer and paper processing system.

The DT-30 digital three-sided cut is designed to meet the requirements of digital post-printing binding. The machine is small and simple, high degree of automation, high precision cutting, and adopts friendly man-machine operation interface. The machine is convenient and fast to operate, which can be connected to production and independent operation to meet various production needs.

Want to know more about our solutions?

Please fill in the form for the personal consulting.

手机浏览

手机浏览