- Introduction

- Details

- Technical Data

-

- Commodity name: Rose-12000 Saddle Stitching System

- Commodity ID: Rose-12000

Rose-12000 Saddle Stitching System is specially designed and firmly built by employing European top quality standards and using the world's leading stitching technologies. It is capable to perform a wide range of stitching formats cost-effectively and in a timely manner. It features on high productivity at speeds up to 12,000 cycles per hour with consistently reliable production, which makes it an ideal choice for medium to large runs.

Rose-12000 Saddle Stitching System

High Production Output with First-Class Quality

Rose-12000 Saddle Stitching System is specially designed and firmly built by employing European top quality standards and using the world's leading stitching technologies. It is capable to perform a wide range of stitching formats cost-effectively and in a timely manner. It features on high productivity at speeds up to 12,000 cycles per hour with consistently reliable production, which makes it an ideal choice for medium to large runs.

Outstanding Features:

♦ High-speed and high productivity up to 12,000 cycles per hour.

♦ Convenient and easy operation through large icon-based SIMENS touch screen.

♦ Large range of stitching formats from 130*80mm to 465*300mm (trimmed book size).

♦ Comprehensive quality control system to ensure reliable and precise stitching.

Machine Layout:

Key words:

Key words:- JMD

- Saddle Stitching

- Saddle stitch binding

- saddle stitch staple

- saddle stitch bookbinding

-

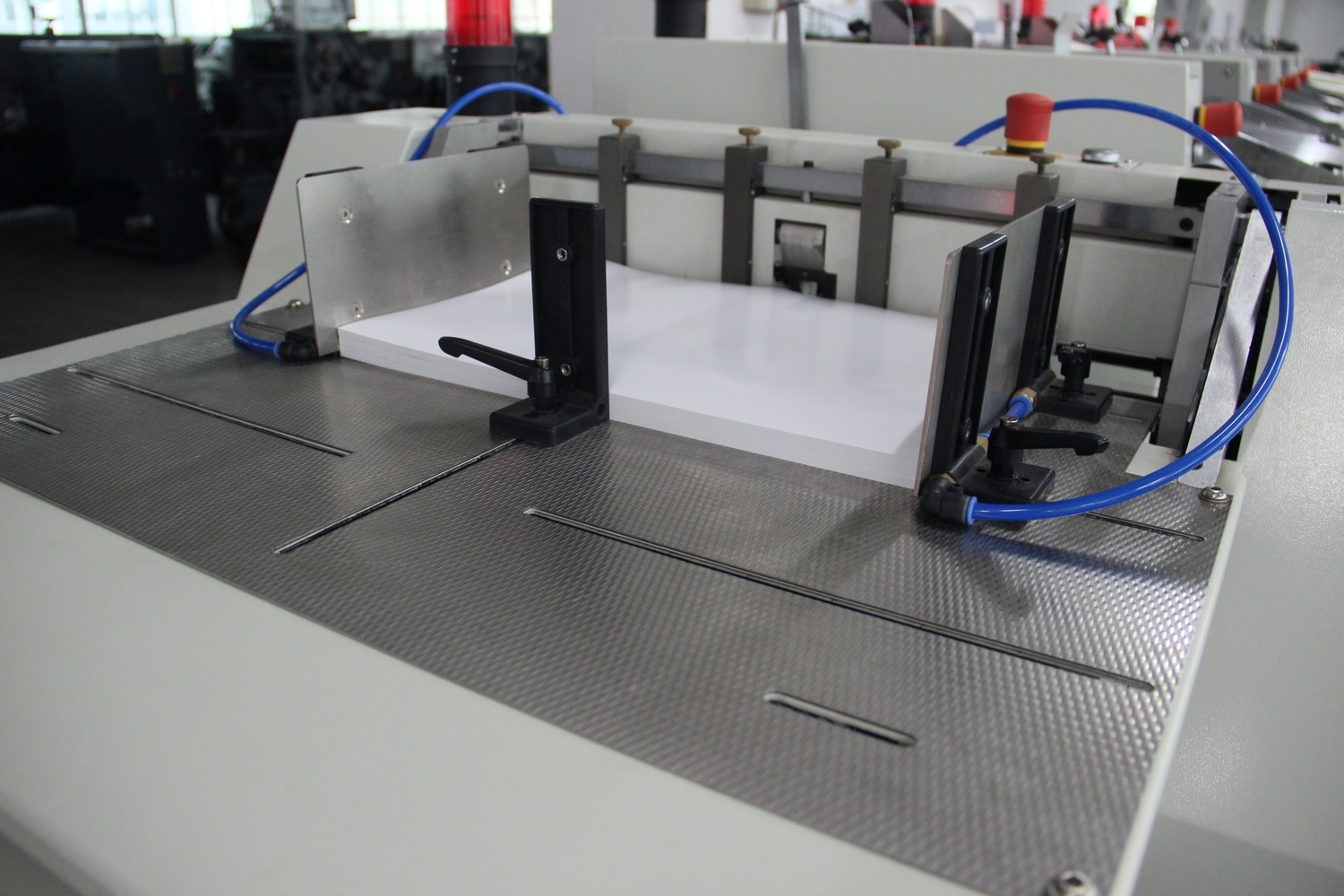

Signature Feeders

All signature feeders can be tilt-back for hand feeding, which makes it possible to realize special signatures gathering.

Signatures with high or low folio laps can be gently opened by grippers. Vacuum opening is provided for signatures without flaps.

1:1 and 1:2 operation modes are available.

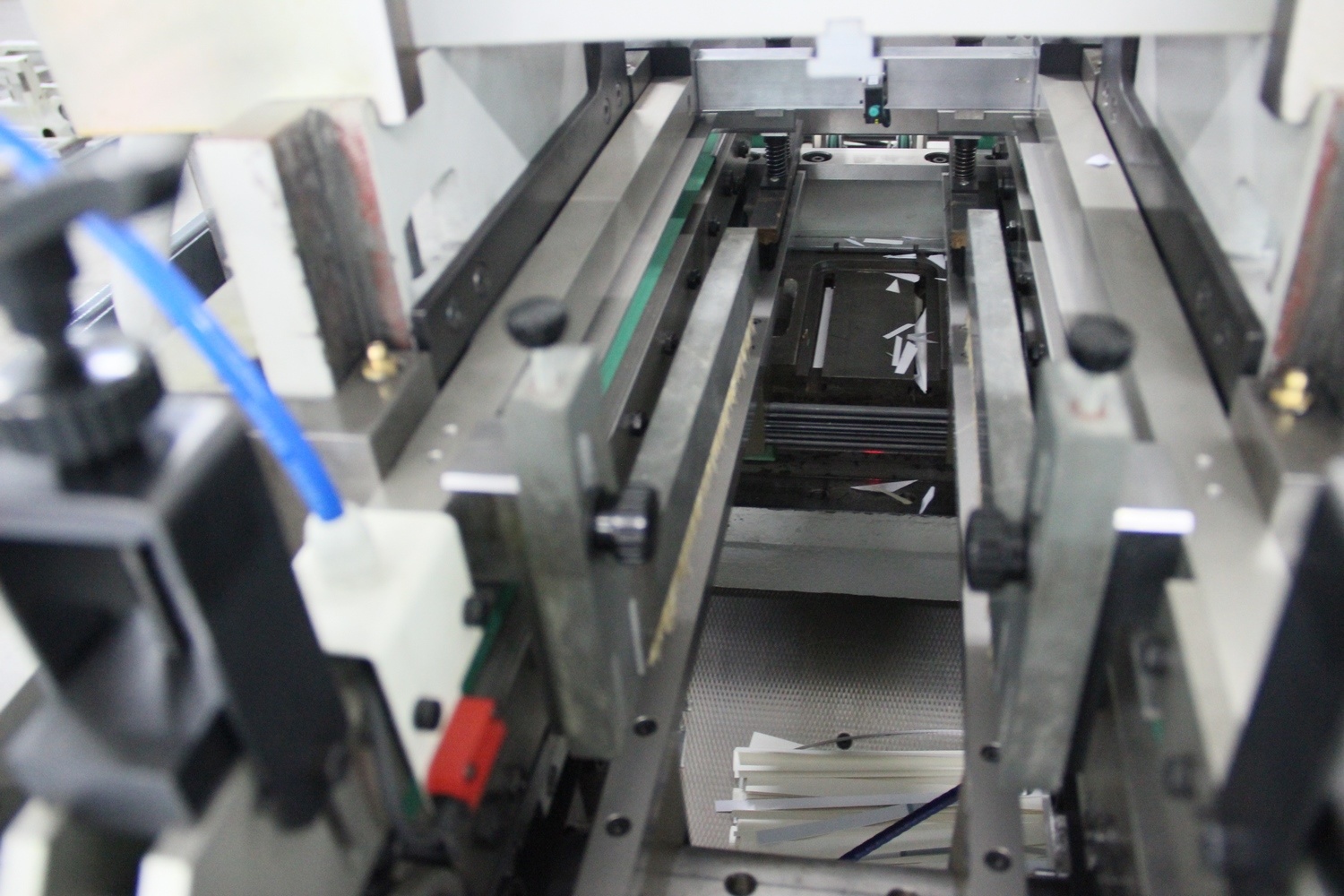

Cover Folder Feeder

After the cover is scored and folded, it will be fed onto the next well gathered book block to form a complete booklet for stitching process.

Comprehensive Quality Control System The comprehensive quality control system can detect miss-fed, multi-fed, jam, bended-signature, non-stitching, or non-signature, which ensures reliable stitching quality, prefect complete products and reduces production waste significantly.

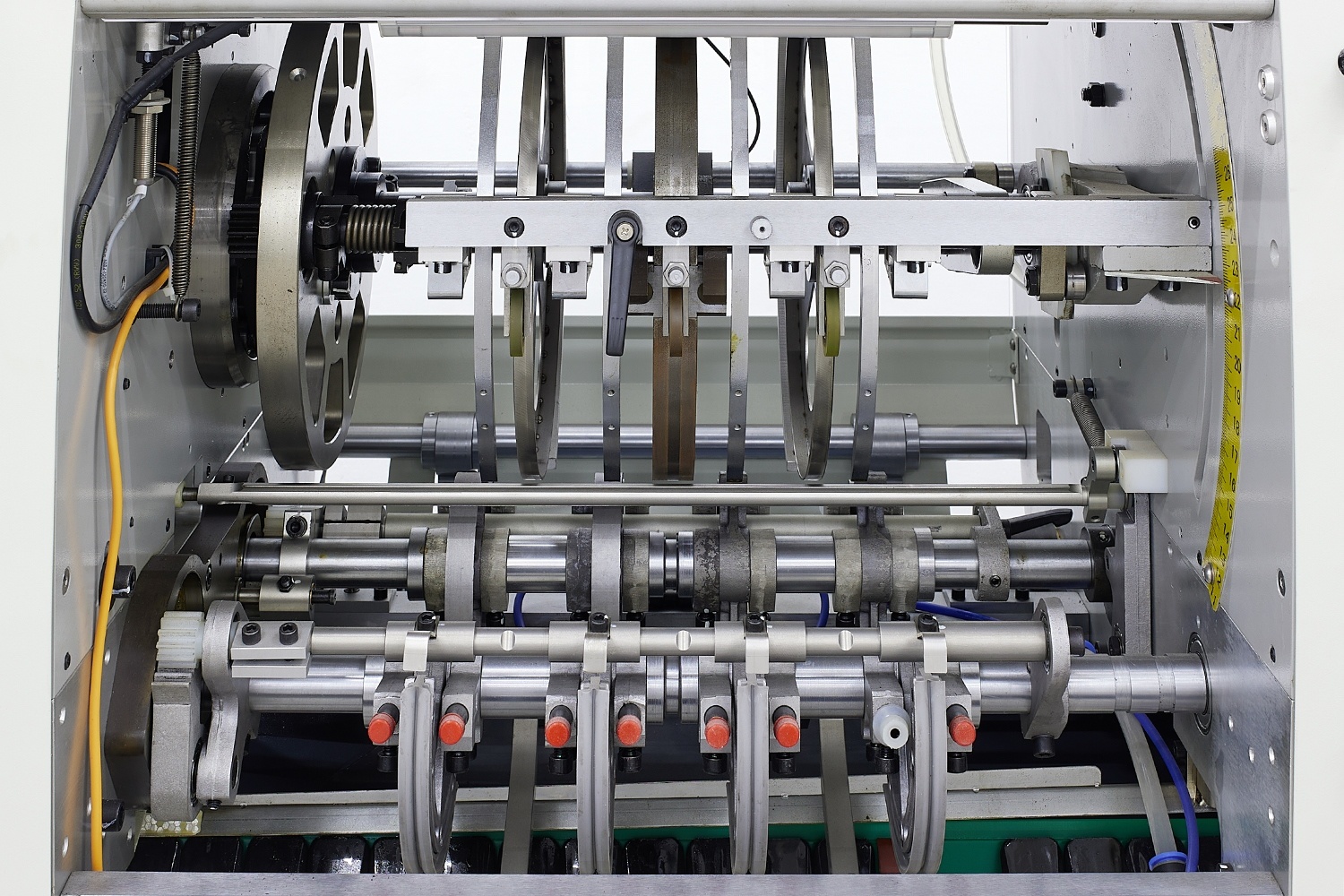

Stitching Unit

The stitching unit configures two Hohner stitching heads for precise and excellent stitching, which can stitch up to 5mm thickness to meet different requirements.

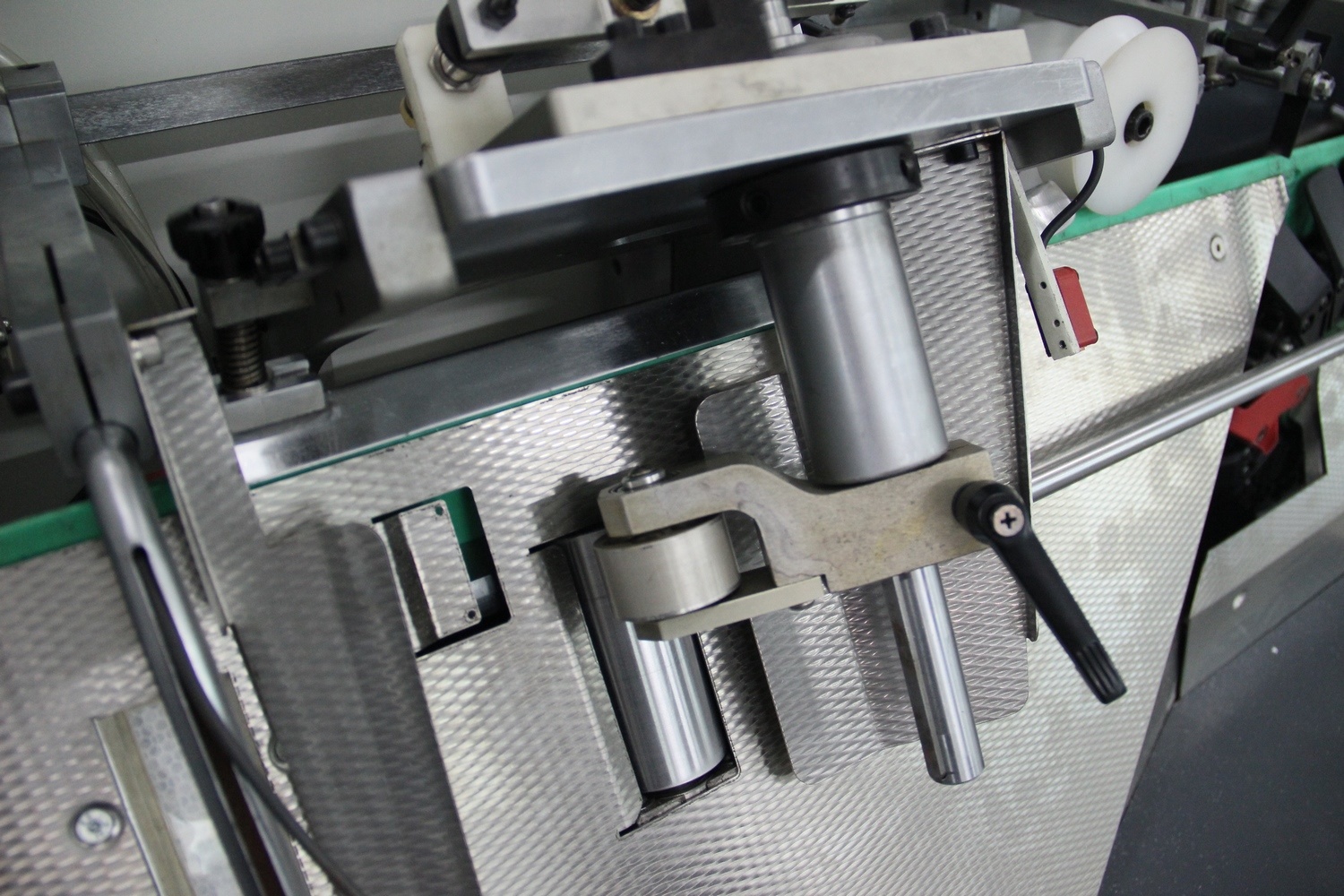

Three-Knife Trimmer

The trimmer is quick and easy to set up using hand wheels with position indicators.

Smooth transferring and precise positioning of each untrimmed book assure that each book is accurately trimmed, first by the front cut knife, and then the head and the foot.

-

Machine Model

Rose-12000

Max. Mechanical Speed

12000 c/h

Max. Untrimmed Book Size (a*b)

470x310mm

Min. Untrimmed Book Size (a*b)

138x105mm

Max. Trimmed Book Size (a*b)

465x300mm

Min. Trimmed Book Size (a*b)

130x80mm

Max. Stitching Thickness (c)

10mm

Power Required

27kW

Machine Dimensions

11700*5900*1450 mm

Pre

Related products

The Pearls-8000 is a cost-effective entry level saddle stitching system from JMD. It can achieve high efficient production at speeds of up to 8,000 cycles per hour with excellent stitching quality. The clearly arranged, compact design and central touch screen control allow the machine operator to monitor the prodution process conveniently. Simple operation combined with the space saving layout makes this machine an ideal choice for commercial runs.

Want to know more about our solutions?

Please fill in the form for the personal consulting.

手机浏览

手机浏览