- Introduction

- Details

- Technical Data

-

- Commodity name: Sunbridge High-Speed Perfect Binding System

Sunbridge-15000 ultra-high-speed intelligent perfect binding line is characterized by its high net output, advanced automation, superior binding quality, and ultra-fast job changeover. These strengths are the result of comprehensive technological innovation and process optimization, including full upgrades to the machine structure, core components, and material selection. Moreover, it successfully overcomes the challenge of maintaining stability during ultra-high-speed operation.

Sunbridge-15000 Ultra-High-Speed Intelligent Perfect Binding System

The Sunbridge-15000 ultra-high-speed intelligent perfect binding line is designed to deliver high net output, advanced automation, excellent binding quality, and ultra-fast job changeovers. These advantages are made possible by a complete technological overhaul and process optimization. The machine features comprehensive upgrades in structure, core components, and material selection, while also overcoming the challenge of maintaining stability at extremely high speeds.

In addition, Sunbridge-15000 offers several future-oriented innovations, such as a rotatable touchscreen, an intuitive dual-screen display system, a newly optimized gluing system with fully automatic glue length adjustment, and an industry-first high-capacity external preheating gluing unit with a one-to-two supply mode. It also includes a more stable and continuous cover feeding system and a newly developed breaststroke-style forming station that ensures precise and strong cover binding. These innovations position the Sunbridge-15000 as a cutting-edge solution for modern, high-efficiency book production.

Outstanding Features

♦ Ultra-High Speed & Efficiency: Reaching speeds of up to 15,000 books/hour, the Sunbridge-15000 sets a new benchmark for perfect binding efficiency in China, catering to the diverse needs of large-scale production.

♦ Fast & Fully Automatic Setup: Equipped with a full-servo control system, it allows quick format changes through intuitive UI touch-screen parameter input. This significantly reduces labor dependency and simplifies the operation process.

♦ AI-Ready Smart Platform: With robust hardware designed for AI integration, the system supports online monitoring, remote diagnostics, self-diagnosis, and intelligent data interfaces compatible with MES systems — paving the way for future smart manufacturing.

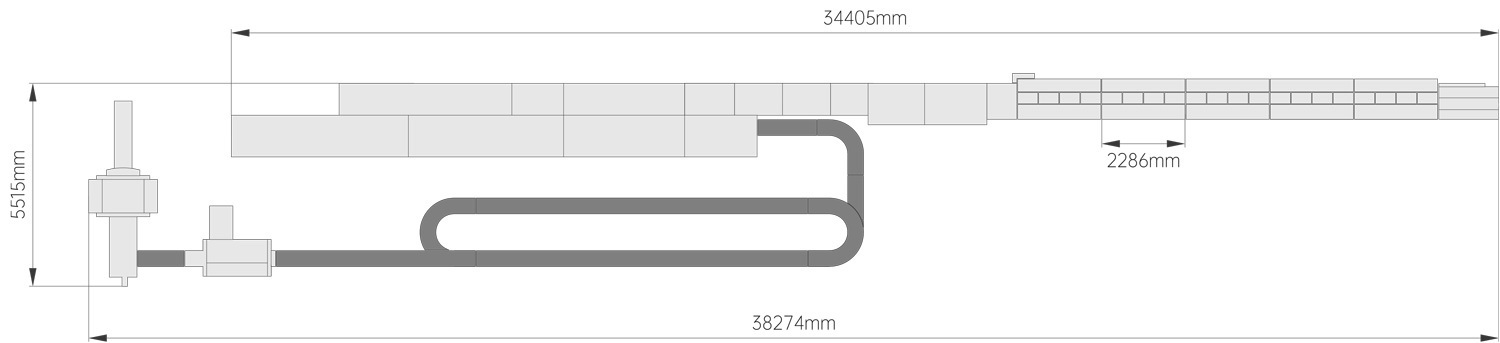

Machine Layout:

-

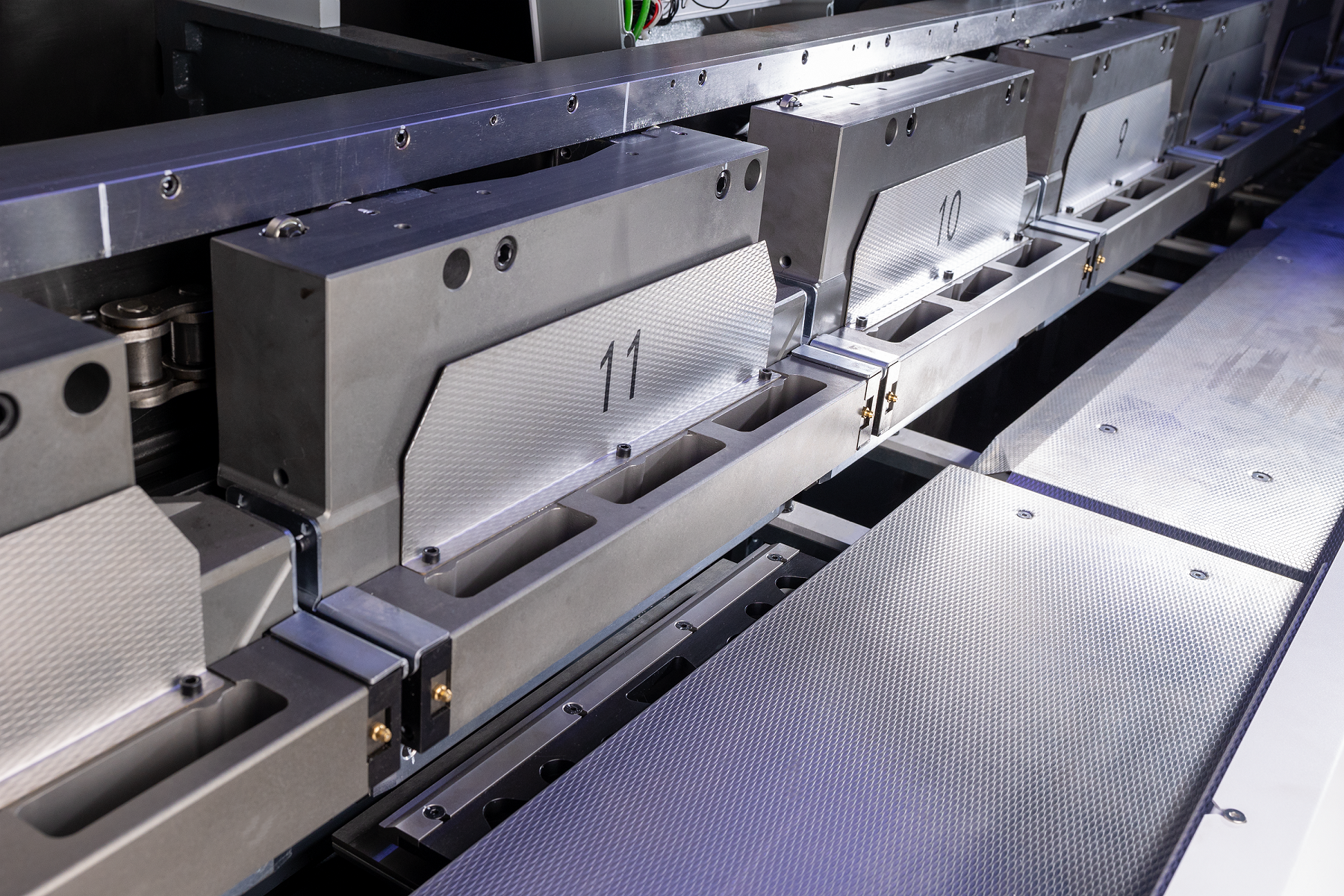

Book Clamp System

The die-cast aluminum alloy book clamps, combined with German-imported torsion springs, ensure reliable clamping force. The clamp opening width is automatically adjustable via Siemens servo motors.

Spine Preparation Unit

Three-station spine milling and notching technology with precision up to 0.1mm.

Combined with an optimized dust extraction system for cleaner waste removal, enhancing glue penetration.

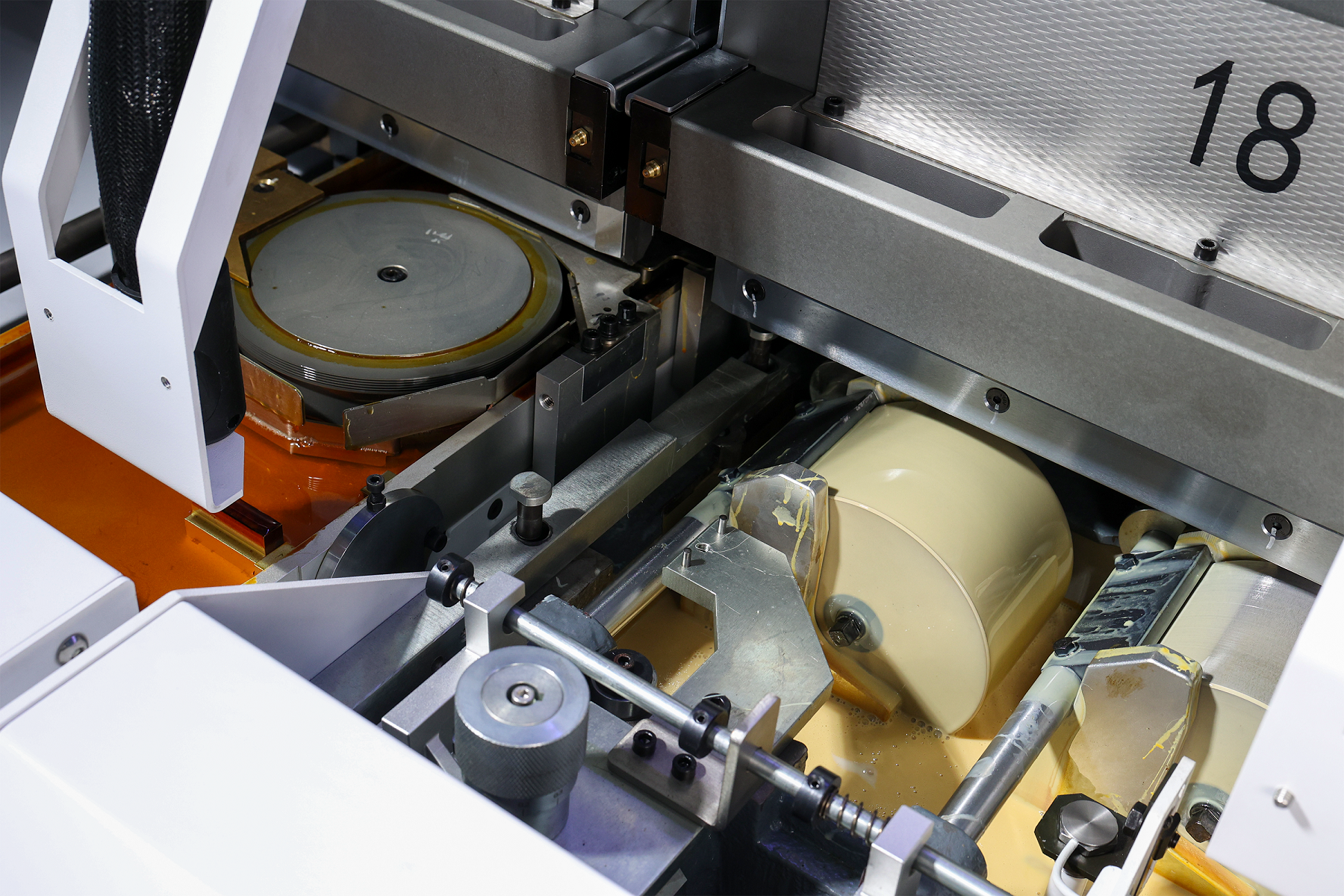

Gluing Application System

The servo motor precisely controls the glue film length, offering easy operation and adaptability to different materials. The large-diameter dual gluing rollers and carefully designed glue application system ensure more even and stronger adhesion.

An industry-first external preheating gluing unit with a high-capacity “one-to-two” supply mode provides greater energy efficiency and environmental friendliness.

Two Nipping Stations

The newly designed breaststroke-style dual cover feeding system offers quiet operation, stability, and low wear.

Double spine pressing ensures firm and precise book spine formation with high clamping quality.

-

Machine Model

Sunbridge

No. of Clamps

32

Max. Mechanical Speed

15000 c/h

Book Block Length (a)

140-420mm

Book Block Width (b)

120-305mm

Book Block Thickness (c)

3-60mm

Cover Length (d)

140-420mm

Cover Width (e)

250-642mm

Power Required 125kW Machine Weight 17,500kg

Pre

Related products

No data

Want to know more about our solutions?

Please fill in the form for the personal consulting.

手机浏览

手机浏览