- Introduction

- Details

- Technical Data

-

- Commodity name: Superbinder-8000e Perfect Binder

- Commodity ID: Superbinder-8000e

Superbinder-8000e is a 21-clamp fully automated perfect binding system with speed up to 8,000 cycles/ hour, which can satisfy the high requirements for both offset and digital printing. It features on high degree of automation, high productivity and outstanding binding quality, which makes it an ideal choice for printing companies to handle various jobs with quick changeover.

Superbinder-8000e Perfect Binder

Superbinder-8000e is a 21-clamp fully automated perfect binding system with speed up to 8,000 cycles/ hour, which can satisfy the high requirements for both offset and digital printing. It features on high degree of automation, high productivity and outstanding binding quality, which makes it an ideal choice for printing companies to handle various jobs with quick changeover.

Outstanding Features:

♦ Full Automation: Fully automated setup and changeover can be performed in a few minutes by simply inputting binding formats into the touch screen.

♦ High Productivity: High production speed up to 8,000 books/hour can be achieved, which increases greatly the net output and cost-effectiveness.

♦ Outstanding Binding Quality: Two spine glue tanks and two nipping stations ensure a strong and accurate outstanding binding effect with perfectly-shaped book spines.

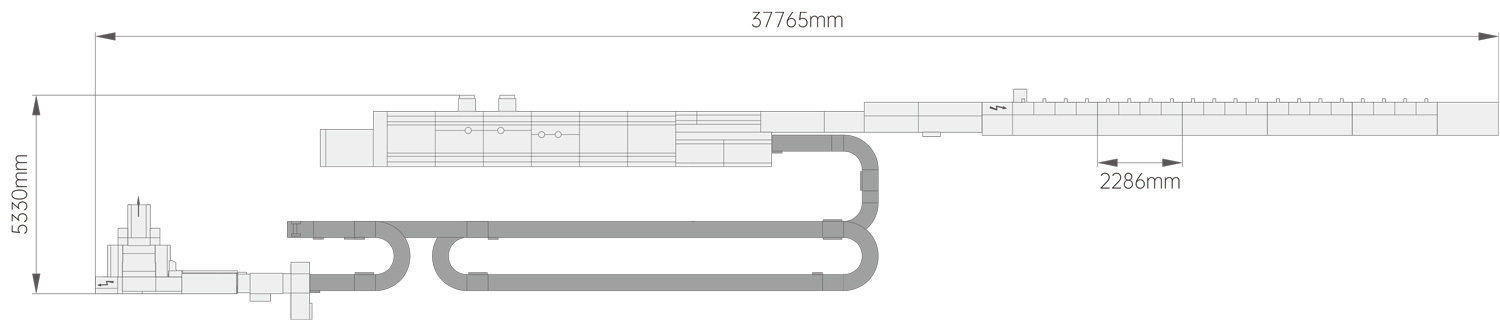

Machine Layout:

Key words:

Key words:- JMD

- book binding

- book binder

- binding machine

- binding machinery

- perfect binder

- glue perfect binder

- book binding machine

- booklet binder

- perfect binding machine

- binding equipment

- softcover binder

- pur binder

- glue binding machine

-

Spine Preparation Stations

Three spine preparation stations provide for spine roughening, milling, notching and brushing.

The opening width and height of the roughening, milling and notching stations are fully automated adjusted according to the setting.

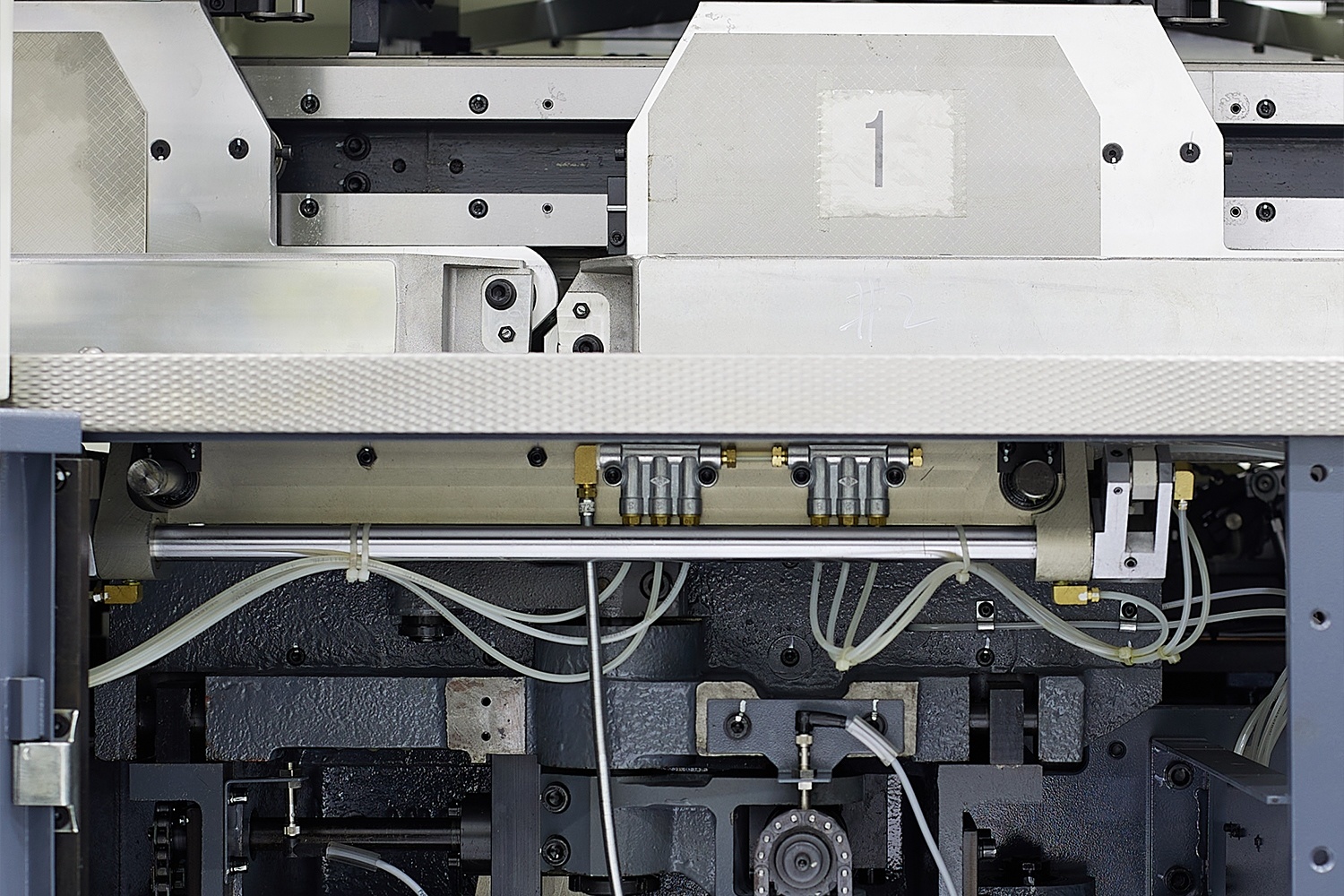

Gluing Application System

Double spine gluing stations with one side gluing station guarantee optimal gluing effect.

The spine glue length and the side glue

rollers opening with are automatically adjusted.

Cover Feeding & Scoring Unit

The specially designed dual-axis scoring rollers of large diameter enable straight and nice-looking scoring lines.

The opening width of cover scoring is automatically adjusted according to the book thickness.

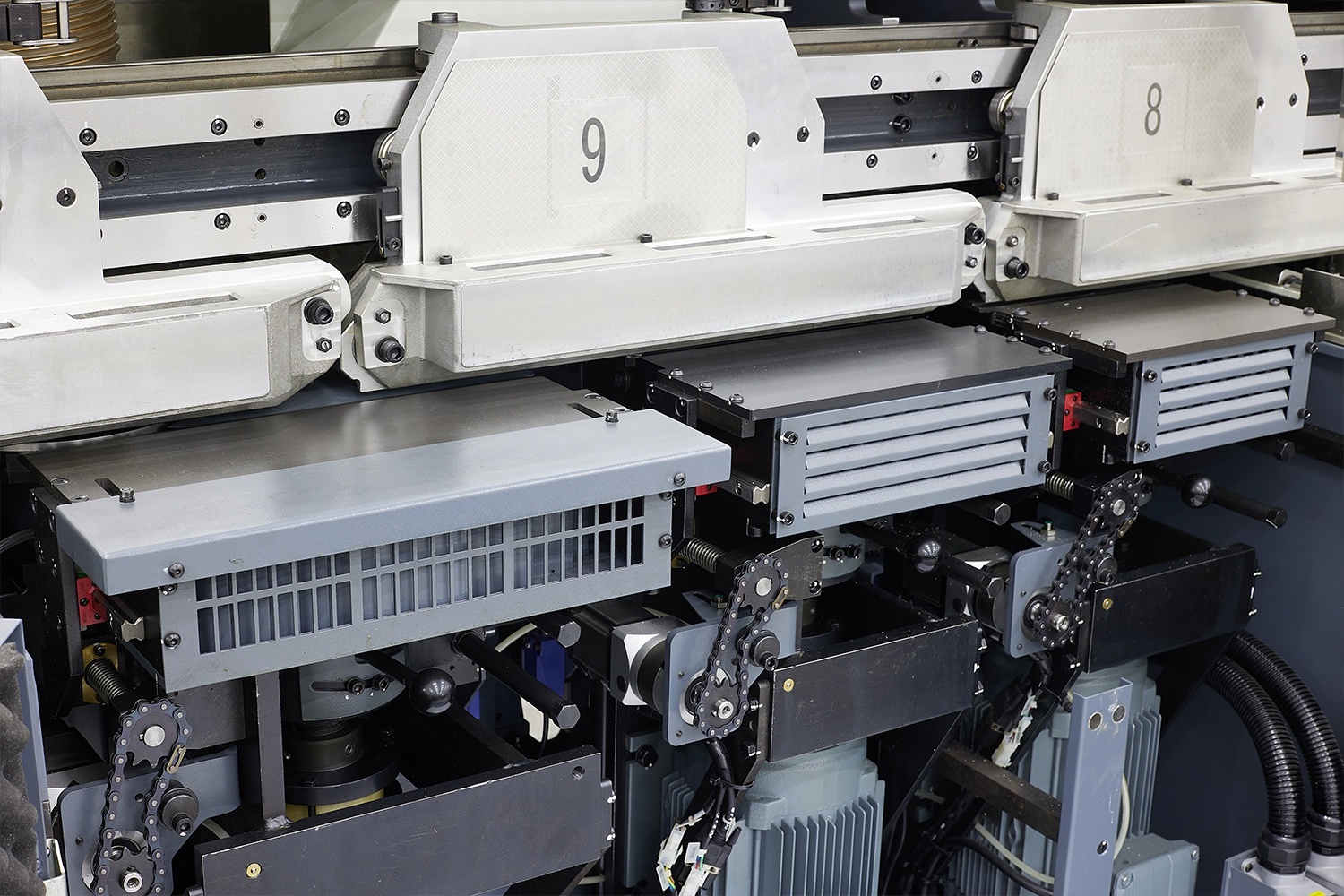

Two Nipping Stations

Two superior nipping stations exert powerful nipping pressure to create strong and durable binds with perfectly-shaped book spines.

The opening width and height of nipping stations are automatically adjusted.

-

Machine Model

Superbinder-8000e

No. of Clamps

21

Max. Mechanical Speed

8000 c/h

Book Block Length (a)

140-460mm

Book Block Width (b)

120-300mm

Book Block Thickness (c)

3-50mm

Cover Length (d)

140-470mm

Cover Width (e)

250-640mm

Related products

The NewBridge is JMD’s latest innovation of fully automatic perfect binding solution with max. speed up to 12,000 cycles/hour. It provides short make-ready time, high productivity and outstanding binding quality, which is an ideal solution for the printing companies to stay competitive in the ever-changing markets and win more opportunities to increase the profits.

The Cambridge-12000 Binding System is the most efficient and the most impressive high performance perfect binding line from JMD. It features high production speed, short make-ready time and outstanding binding quality. Cambridge-12000 Binding System is an ideal choice for large printing houses to improve production efficiency and save labor cost.

Superbinder-7000M is an ideal binding solution to fulfill your every demand for high production efficiency and quick return of investment. It features easy operation and setup, double spine gluing stations and double nipping stations for perfect spine forming.

Want to know more about our solutions?

Please fill in the form for the personal consulting.

手机浏览

手机浏览